In electronics manufacturing, the testing process can often be delayed due to hardware availability and/or other logistical issues. These delays can hinder progress, but adding simulation capabilities to your automated hardware test system can help keep development moving forward efficiently.

Early Error Detection

Simulation allows for the identification and correction of design flaws early in the development process, before any physical prototypes are built. This can prevent costly revisions later and helps ensure that the hardware will function correctly under various conditions.

Cost Reduction

Building multiple physical prototypes to test different scenarios can be expensive. Simulation offers an alternative by enabling comprehensive virtual testing without the need for additional hardware. This reduces costs and allows for more extensive testing and validation.

Testing Under Varied Conditions

Simulations can replicate extreme conditions and stress tests that might be difficult or risky to conduct with physical hardware. This allows for thorough testing of the hardware's performance under a range of environmental and operational scenarios.

Enhanced Flexibility

Simulated environments make it easy to adjust configurations or test parameters quickly, which is often time-consuming when working with physical hardware. This flexibility ensures that more testing scenarios can be covered, improving the robustness of the final product.

Efficient Debugging

Simulation tools provide detailed data that can aid in diagnosing issues during development. This makes it easier to debug and optimize both hardware and software, reducing the time and resources needed for troubleshooting.

Continuity of Development

When physical hardware is not yet available due to long lead times or supply chain issues, simulation allows for continuous development. This ensures that projects stay on schedule and that teams can proceed with testing and refinement without delay.

Parallel Development

Simulation enables parallel development processes, where different teams can work on software and hardware simultaneously. This synchronization reduces the overall development time and ensures that the final product is thoroughly tested and ready for deployment.

Using LabVIEW to Simulate Your Test System

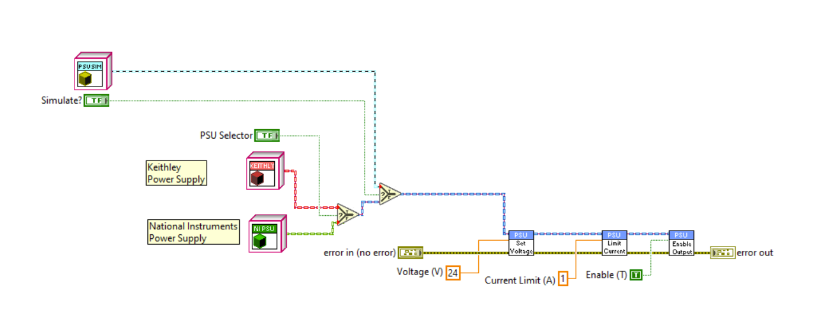

LabVIEW provides powerful capabilities for integrating simulation into automated test systems through the use of simulation classes. These classes allow developers to model hardware behavior, enabling software development and testing to proceed without needing the actual hardware. By using simulation classes, developers can create virtual instruments that mimic the interfaces and behaviors of real-world devices.

Continuing on from our recent blog post

Why Every Great Automated Test System Starts with a HAL, we can extend the HAL capabilities to include a simulation class. Below is an example of such extension using a new "PSU SIM" LabVIEW class.

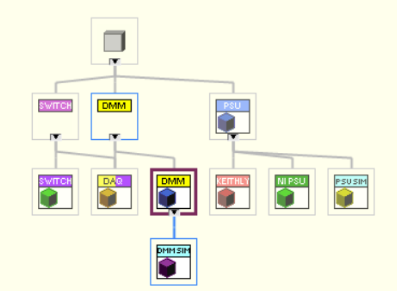

LabVIEW HAL Diagram with Simulation Classes

With simulation classes, you can define different operational states, inputs, and outputs for your virtual instruments, making it possible to simulate a wide range of scenarios and conditions. This is particularly useful in environments where hardware availability is a bottleneck or when testing needs to cover extreme or rare conditions that would be difficult to replicate with physical hardware.

The LabVIEW class hierarchy of simulation classes could look as follows: Each generic concrete device could extend to a more specific simulation device class. This flexibility allows you to test your entire system with or without hardware, as shown below.